Fluid control systems are at the core of industrial automation since they facilitate high performance and integration of various processes. Pneumatic butterfly valves are pivotal components of such systems as they provide accurate control of the flow in numerous processes. There are numerous factors to consider when sourcing pneumatic valves to ensure that the specific requirements of the industrial automation project will be met. This article covers the key factors when sourcing pneumatic butterfly valves, as well as, the impact of choosing the right pneumatic valve supplier on the success of your automation project.

Recognizing the Use of Pneumatic Butterfly Valves

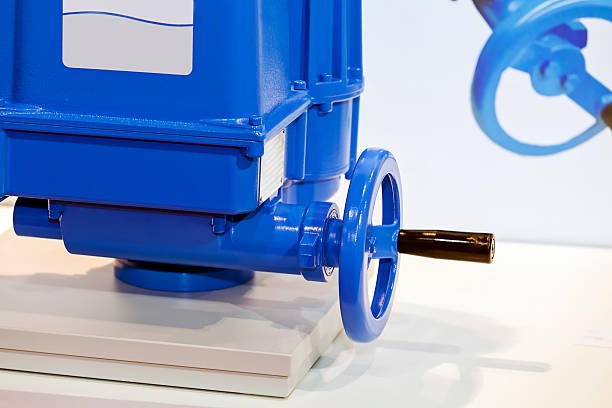

Usually cited as some of the most common types of valve actuators in the control of liquids and gases in motion, pneumatic butterfly valves are widely used throughout industrial automation. Butterfly valves are actually a valve with a revolving disc that serves to control the amount of fluid being let through the valve body. The pneumatic actuator supplies air, and the disc lifts and enables flow through the valve or shuts and stops flow. Simple in design and fast in operation, pneumatic butterfly valves are best suited for applications that need prompt flow modulation. One other reason why these valves are preferred in industries where the fluid control is critical is because of their high capacity for accurate flow measurement.

In addition to providing fast acting features over other valve types, the construction of pneumatic butterfly valves is compact which translates to saving a lot of space within an industrial facility. Integration to the existing infrastructure is simple especially in tight areas within industrial systems because their compact construction tends to exceed accepted industry norms. On top of that, the variety of pressures and types of fluids that can be used to operate the pneumatic butterfly valves showcases their versatility and ability to be used in a wide range of industrial uses. As with any other electromechanical device, use of low maintenance materials during construction coupled with the compact design translates to making them ideal for long term continuous use.

The Significance of Selecting Appropriate Materials

The construction material used in manufacturing pneumatic butterfly valves is of utmost importance as far as sourcing is concerned. The material of the valve body and seals affects not only its durability, but also its compatibility with the fluid or gas being controlled. As an illustration, the materials for the chemical process valves may be built from some stainless steel that are corrosion resistant to withstand aggressive chemical usage. Similarly, hygiene requirements for food and drink applications dictate the use of contaminant resistant materials.

Pneumatic valve dealers have many types of materials which cut across various environments. Taking advantage of cheap materials is often a false economy since critical services are likely to be compromised. Also, materials have to be chosen depending on the temperature and pressure conditions which the valve will be exposed to. By selecting the right material, valve degradation can be minimized which increases the overall system efficiency and longevity of the valve. Moreover, certain industries are obligated to qualify for stringent regulations such as those set by the FDA. These will also affect the material selection.

Vale Size and Flow Capacity

In the process of sourcing pneumatic butterfly valves for industrial automation projects, a special note is paid to size and flow capacity. A valve is as good as its size, for it has to match the system piping and flow rate to guarantee optimum performance. The usage of a valve that is small as compared to the required level will limit flow and put pressure on the system and efficiency. On the contrary, a valve that is too big will needlessly consume energy. The correct valve size is a compromise and ensures that the flow is designed to optimum level, thus avoiding system breakdowns.

Determining the appropriate size involves assessing the system flow by surveying its fluid or gas type, pressure conditions, and flow rates. Working with a reliable pneumatic butterfly valve supplier can help ensure that the valves selected for your project are sized correctly to handle the specific flow requirements. Proper positioning of valve sleeves not only brings forth system performance but also efficiency and costs in the future. Choosing the right valve size makes sure that the system is in operation all the time while reducing operational interruptions saving both productivity and cost.

Actuation, Control Features, Reliability and Maintenance Needs

Operation of actuators in pneumatic butterfly valves is critical for its functionality. The movement of the valve is coordinated by a pneumatic actuator and, therefore, the valve operation is quick and reliable. When purchasing pneumatic valves, the type and The actuators have to be specified. Pneumatic valves used in spring return actuators or double actuators differ in their functions and time served to respond.

Actuators differ because of the speed, pressure ranges and control mechanisms. Considering a situation where a valve needs to be operated repeatedly, a fast-acting actuator should be used. Moreover, confirm that the actuator does not fit the system’s control structure, which is often found in automated systems. Signaling the actuator to the control system eliminates the need to manually operate the valves, thus enhancing the effectiveness of an efficient system, and reducing the chances of the system breaking down. Changing the operational conditions of industrial systems can easily be done using pneumatic actuators and it improves performance.

The industrial automation project’s reliability is essential, for a fault with a single valve could result in expensive system damage or prolonged downtime. As much as the reliability of the valve itself is important, the sourcing of pneumatic butterfly valves also considers the reliability of the valve actuator. Sustained performance over time is characteristic of high-quality valves supplied by reputable pneumatic valve suppliers, as they are built to withstand extreme conditions. Other performance factors that have to be taken into consideration include maintenance. In general, pneumatic butterfly valves need less maintenance, although routine service and inspection are critical to ensuring continual smooth operation. When selecting a valve, factors such as disassembly, cleaning and component replacement should also be considered. To reduce downtime and maintenance costs, and most importantly – ensure that the valve continues to function optimally, it makes perfect sense to choose a supplier that offers support services alongside valves containing easy to replace components.

Conclusion

When sourcing pneumatic butterfly valves for industrial automation projects, one must pay attention to a few overarching factors, such as valve material, valve dimensions, actuator type, reliability, and maintenance needs. A credible supplier of pneumatic valves guarantees that the valves supplied are perfectly compatible with the rest of the components of the system and are able to serve the purpose of scope to reliability. Target high flow rates, suitable materials, and responsive actuators so that your pneumatic butterfly valves are effective and efficient, increasing the level of success in your industrial automation project.